The making of an analogue time piece.

A bit over a year ago we rather ambitiously went on a frenzied but rewarding mission making everyone's Christmas presents. I managed to document some of the projects in a timely manner, but lost steam half way through, letting the process photos gather the digital equivalent of dust and cobwebs. Perhaps, it's time to unearth another one of those undertakings.

One gift I didn’t have to think hard about for a clock for my other

half. Well, there was a lot of thinking

involved, but that involved resolving the design details as opposed to coming up

with the concept. We have a

garage/workshop, which is my husband’s greasy second home. He didn’t have a clock and couldn’t get his

phone out of his pocket with filthy hands to check the time, so there were

frequent issues with punctuality, especially around dinner time. I set out to resolve this persistent concern

with something of design significance to this wonderful man: his 1971 MGB race car.

|

| MGB in action. Photo taken by some race meeting photographer |

I had the design finalised by mid November and cut the first

prototype. I gleefully patted myself on the back for being so organised with the whole Christmas whatsitnow. The plywood clock face had

the design engraved into it, and then the design was cut separately out of card

and inlaid into the wood recess. It

worked perfectly, so I sent the files to the fabricator to have the inlay

components cut out of brass. After not

hearing back from them for a few weeks, I got slightly anxious and called them, only

to be told that they couldn’t cut brass and that they had emailed me about the

issue. The email must have been eaten by

the internets because I never received it.

I really wanted the vintage look of brass, but by then it was too late to find another

fabricator, so I made the decision to use stainless steel instead. At least that would match the chrome of the car.

|

| Plywood and card mock up. The card pieces fit perfectly into the laser engraving in the plywood |

I

firmly decided to avoid a last minute mad making panic A La Design

School, so I forcefully crossed my fingers in hope of getting my parts back on

time. I couldn’t work on any other

components until the metal parts arrived, so when I was told ten days before

the deadline that my files were unreadable (despite being especially converted

for industrial CAD cutters), I developed a persistent twitch to accompany my morning

sickness. What followed was a series of

phone conversations with the fabricator where I had to convince them that the

design was to be cut exactly as specified – I’d already prototyped it, and it

worked, and no extra bridges were needed. Yes, yes Cut As Is, Please I Know What I'm Doing scenario.

Finally,

on the 21st of December, at the end of the work day, I had the parts personally delivered by the lovely factory manager. I gave him tasty jam to say "thank you".

|

| Thank You jam |

I spent the next morning

frantically and painstakingly grinding off the unavoidable bridges between the

laser piercing points to get my parts out of the unyielding sheet. I wished I had a Dremmel and not a gutless little rotary tool. Anyone who’s worked with stainless steel is familiar with its pervasive attribute for eliciting coarse language. After much swearing, sweating and bleeding I

had all the metal bits separated and laid out.

Fortunately, the parts turned out about 95% accurate to the design,

which meant only minor tweaking of the original drawing to get the engraving of

the clock face identical to the unchangeable stainless components.

|

| Grinding off waste material |

|

| Steel parts ready for cleaning |

Next came the inlay prep work. Firstly, when you laser cut wood, you can't just grab the cut part and expect it to be good enough for a product. I see those examples in the market place all the time, and it bugs the hell out of me. A laser beams is basically a very concentrated fire. It burns. Intensely. People seem to be surprised by that. The heat causes charring on the material surface, in the direction of the pull of the extraction. Quite a bit of sanding is required to tidy up the laser cut parts.

|

| Sanding the clock face |

|

|

|

After all that grind, it was time for some serious effort to inlay the

springy, shiny steel parts into the engraving without making a mess. Getting the intricate MG cut-out to stay flat was remarkably difficult and incredibly frustrating.

|

| Gluing in the metal parts |

|

| Oh the terrible glue mess! |

|

| Painstaking sanding the glue off the plywood without scratching the metal |

|

| Tidied inlay |

|

Next step is sealing the clock to make sure that the wood lasts well. I decided on a spray lacquer. Unfortunately I couldn't get into a ventilated paint booth, so had to do the spraying outdoors, at the mercy of Wellington wind.

|

| Deciding between a wax and a lacquer. Wax and metal should have been quite obviously a dumb idea. |

|

| Spray lacquering in a mostly sheltered alleyway. The back clock panel is thick enough to accommodate the mechanism |

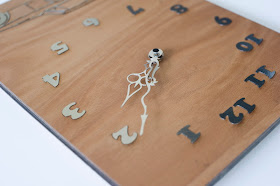

I was on the receiving end of some suspicious looks from people who must have mistaken me for a tagging delinquent. Several lacquer coats later the clock face was ready for its pointy hands. I bought a cheap clock mechanism and swapped its paper thin aluminium hands for my custom cut ones. Two days before Christmas the clock was finally complete and ready to be packaged into an insanely beautiful box made from some cardboard scrap.

|

| Nothing beats a brown cardboard box |

|

| Leather MGB gift tag |

The clock has been a functional workshop feature ever since.